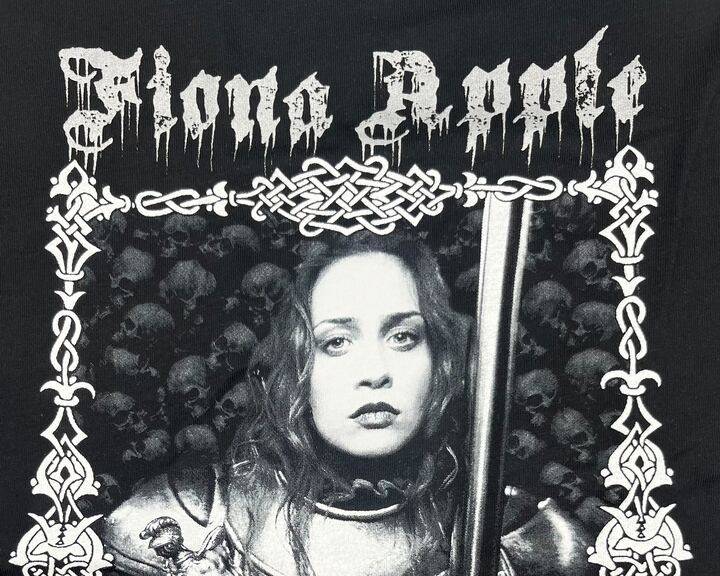

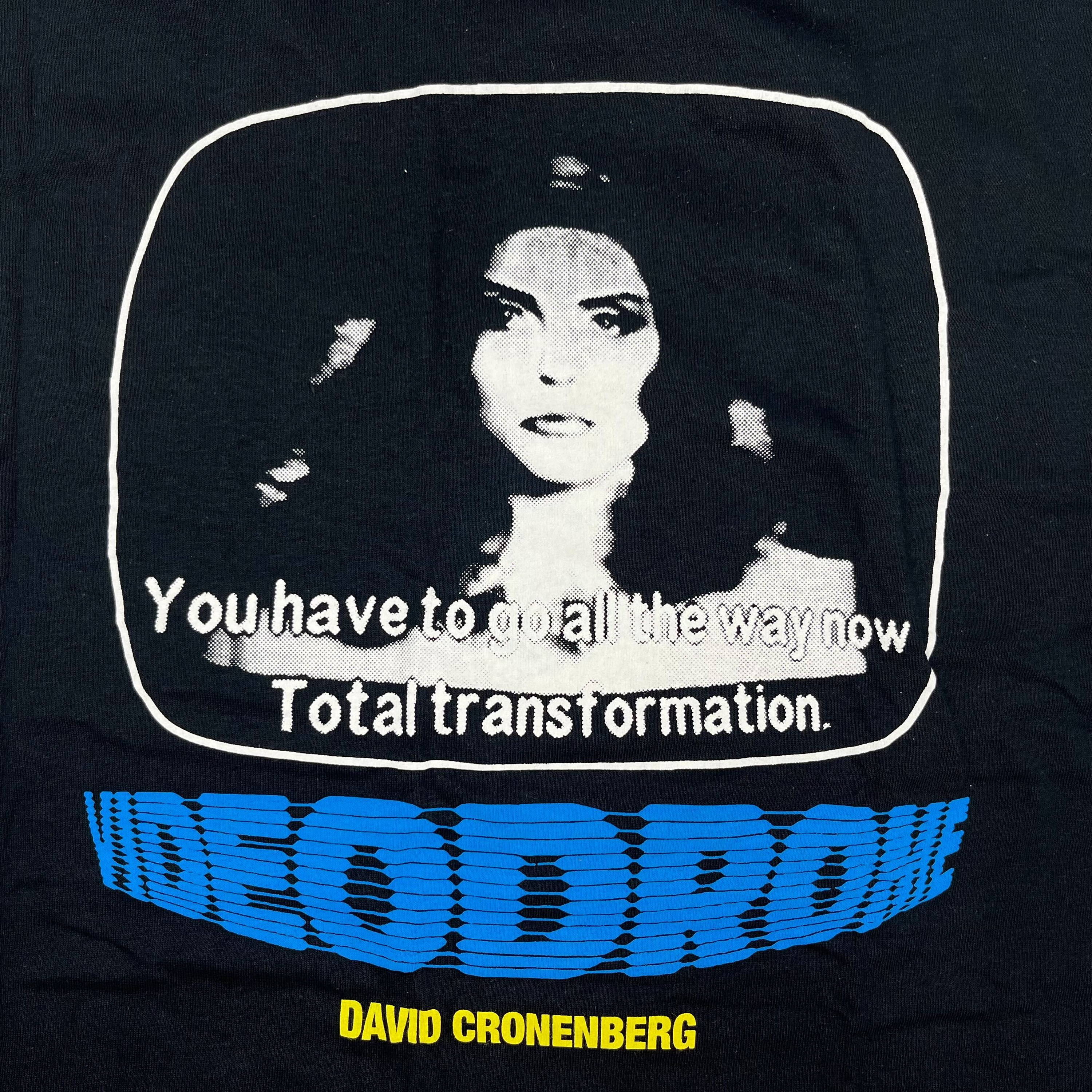

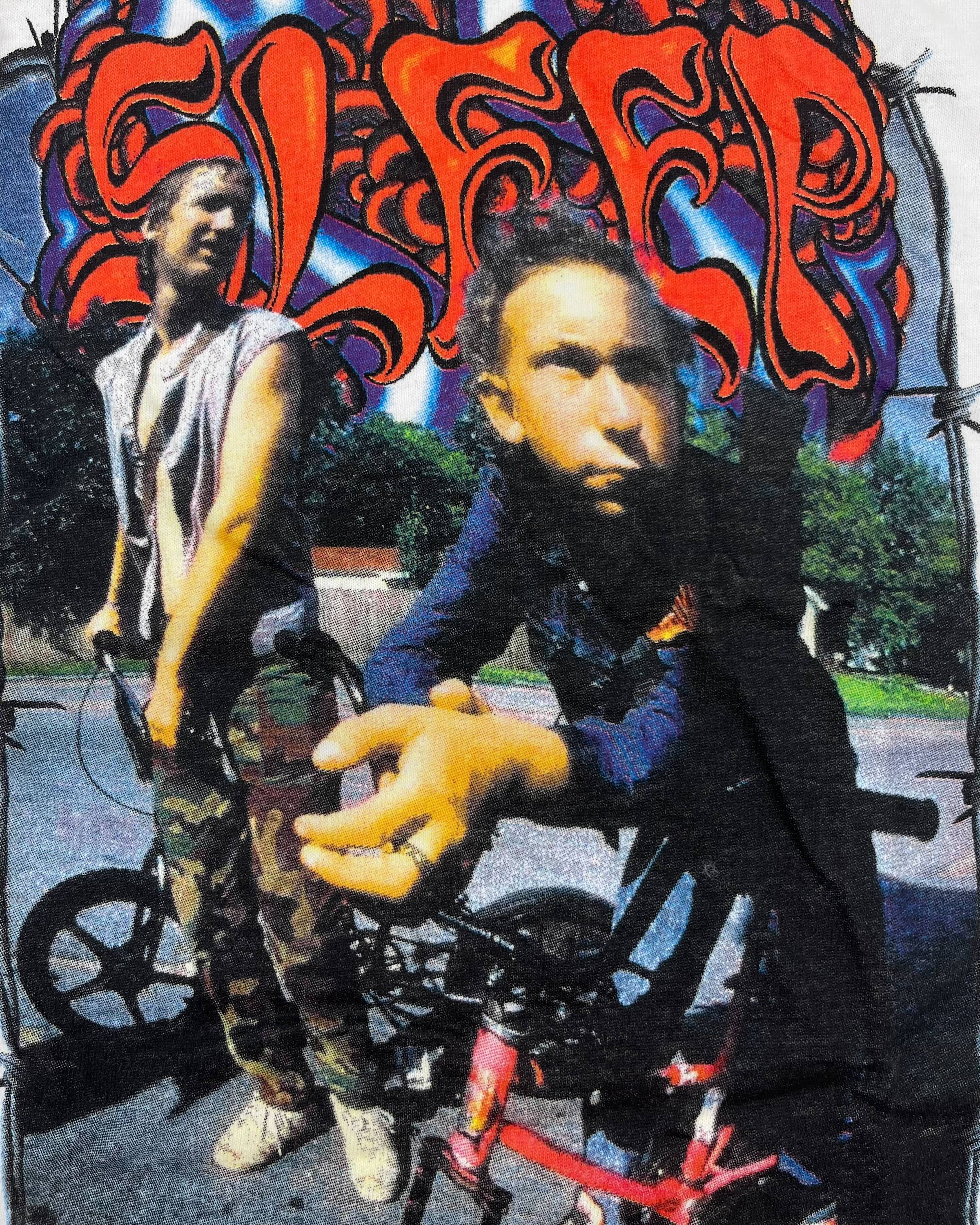

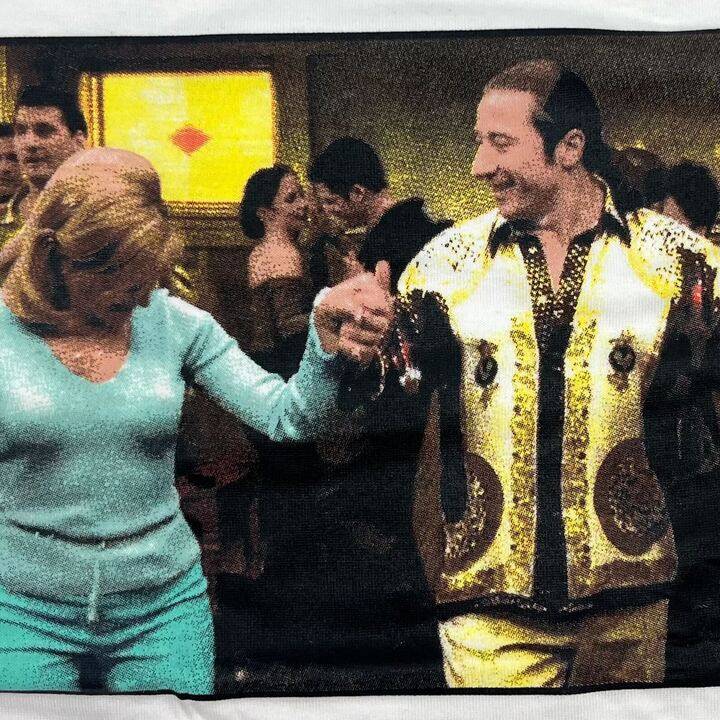

This printing method is a process print, meaning tiny dots of a few colors make many colors. In this case, it’s cyan, magenta, yellow and black. This method is good for photographic images on light-colored shirts that contain a good amount of cyan, magenta, yellow or black.

Pros: Fewer screens, full color

Cons: Narrow color gamut